by Daniel Maiese | March 22, 2018

Biopharmaceuticals—medicines produced from living cells—have emerged recently and already are having a revolutionary impact on vexing diseases such as cancer.

But meeting the demand for these treatments requires a faster, more streamlined manufacturing process for making safe, efficacious medicines in the future.

The National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL), headquartered at the University of Delaware, is at the forefront of making these medicines more accessible to Americans.

Sponsored by the Commerce Department’s National Institute of Standards and Technology (NIST), NIIMBL is one of 14 institutes in the nation’s Manufacturing USA network, designed to increase U.S. competitiveness in manufacturing.

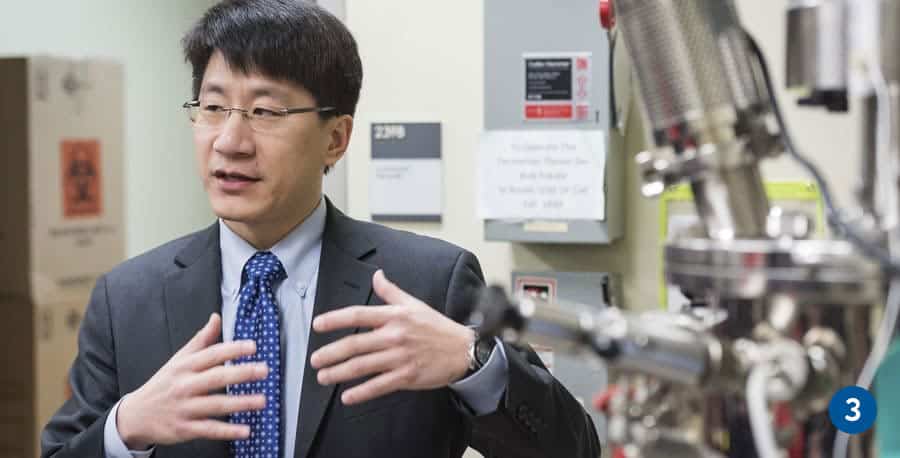

The NIIMBL proposal, steered by UD’s Kelvin Lee, Gore Professor of Chemical and Biomolecular Engineering, was selected by NIST in late 2016, with UD as the lead institution. The University last fall broke ground on a new six-story, $156 million Biopharmaceutical Innovation Building that will house NIIMBL and other initiatives on UD’s STAR (Science, Technology and Advanced Research) Campus.

The goal is to connect the region’s deep expertise in chemical engineering and pharmaceutical sciences with the STAR Campus, where industrial, academic and federal partners can work together to expedite the needed advances and innovations.

“UD has a long history of significant contributions in the fields of manufacturing, materials and engineering, exemplified by Nobel laureate Richard Heck’s work that revolutionized pharmaceutical manufacturing,” said University President Dennis Assanis. “We are committed to developing the innovative tools and techniques of tomorrow’s advanced-manufacturing facilities. We are also proud to contribute our efforts to improve the well-being of individuals and society.”

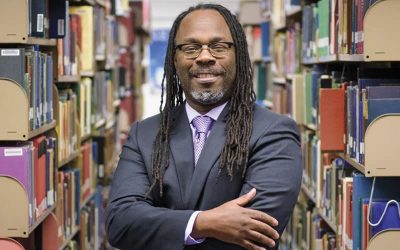

ABOVE: 1. UD President Dennis Assanis (above) applauds the NIIMBL team at the ceremony announcing its headquarters at the University of Delaware in December 2016. Photo by Evan Krape. 2. U.S. Sen. Chris Coons championed creation of the Manufacturing USA Network, which is geared to increase U.S. competitiveness in manufacturing. 3. Kelvin Lee the Director of NIIMBL 4. Jennifer Mantle, NIIMBL’s regulatory committee coordinator, at work in the laboratory at UD.

Operating as a large consortium, NIIMBL is supported by $70 million from NIST—the single largest federal award UD has received to date. In addition, partners from industry, academia, nonprofits and state and local governments have added $180 million more for a total investment of $250 million over the initial five-year phase. The money will provide considerable spark for this national innovation and education engine, said Lee, now NIIMBL’s director.

“Its success will reach far beyond the walls of a lab or manufacturing facility,” Lee said. “The work NIIMBL does to bring new medicines to market faster will have a significant positive impact on patient health. Further, its commitment to workforce and educational training programs promises significant economic impact by creating new jobs.”

How NIIMBL Will Help

With partners in industry, academia, nonprofits and government, NIIMBL convenes a unique and robust set of insights and expertise to address challenges in a more efficient, cost-effective way.

The goal is to help bridge the proverbial “valley of death” between academic research and industry needs—the point where investment is needed to turn a concept into a prototype and to determine the feasibility of commercial production.

“The collaborative aspect of NIIMBL will be essential to solving today’s biomanufacturing challenges and creating an environment where this industry can thrive, particularly in the U.S.,” Lee said.

One key feature of Manufacturing USA institutes in general, and NIIMBL in particular, is an emphasis on support for small and medium-sized enterprises (also known as SMEs). SMEs are often the wellspring of innovative methods and technology. However, the size and limited funding available to SMEs can make it difficult for them to advance their interests. NIIMBL’s collaborative model will enable SMEs to build prototypes and perform demonstration projects. It also will work with the federally funded Manufacturing Extension Partnership (MEP) that has centers around the country, including at Delaware Technical Community College, to support the needs of SMEs.

Biopharmaceuticals vs. traditional drugs: How are they different?

When you reach for an aspirin to ease a thumping headache, you’re availing yourself of one of the world’s most common drugs. Launched by Bayer in 1899, aspirin was administered by doctors to patients in powder form at first. In 1915, aspirin became the first over-the-counter medicine available to the public.

Like other traditional drugs, aspirin is produced from chemicals. Its structure has just 21 atoms—nine carbons, eight hydrogens and four oxygens. Chemical reactions bond these atoms into molecules. Trillions of these molecules make up a single aspirin tablet.

Biopharmaceuticals, however, have been around only since the 1980s. They are large, complex molecules, with up to 25,000 atoms. As the name implies, biopharmaceuticals are produced from living systems—such as yeast, bacteria, plant or animal cells. These cells may be genetically modified to make certain drugs, meaning that DNA is inserted into the cells to get them to express a specific protein that will knock out a disease agent.

With their high efficacy and limited side effects compared to chemically derived therapeutics, biopharmaceuticals are revolutionizing medicine. Drugs like Lantus for treating diabetes, Herceptin for breast cancer, and Humira, for rheumatoid arthritis and Crohn’s disease, are among the biologics that are saving lives.

Training a world-leading workforce

A skilled, highly trained workforce also is needed to ensure these new processes and standardization methods are carried out properly.

NIIMBL’s workforce development and education efforts are crucial to its mission and focus on creating the right skills in those who want to help manufacture medicines and realize the benefits of high-wage jobs that are characteristic of the industry.

Training will be offered in a variety of programs—including online and hands-on opportunities—and will be hosted by a national network of technical and community colleges.

Biopharmaceutical Manufacturing Challenges

While a series of tightly controlled chemical reactions is used to produce conventional drugs, biopharmaceutical production is a vastly different world. Because living cells are used, greater monitoring, observation, control and analysis at all points is required to ensure that these biological products are effective and meet safety requirements.

While a series of tightly controlled chemical reactions is used to produce conventional drugs, biopharmaceutical production is a vastly different world. Because living cells are used, greater monitoring, observation, control and analysis at all points is required to ensure that these biological products are effective and meet safety requirements.

This more challenging manufacturing process can be expensive and time-consuming. Even the leading biopharmaceutical producers find it challenging to get new therapies to market quickly.

ABOVE: UD broke ground on STAR Campus in October 2017 for a six-story, $156 million Biopharmaceutical Innovation Building. NIIMBL headquarters will occupy about 25 percent

of this state-of-the-art facility. The building will house some of the nation’s top innovators and scientists under one roof, focused on finding cures and improving treatments for Alzheimer’s, Parkinson’s, diabetes, cancer and other diseases.

Bringing communities together

NIIMBL hosted its first national meeting in Washington, D.C., in May 2017 and is preparing now for its 2018 meeting. The initial gathering drew senior government officials, including U.S. Sen. Chris Coons from Delaware and Congressman Tom Reed from New York, FDA Center for Drug Evaluation and Research Director Janet Woodcock, FDA Center for Biologics Evaluation and Research Director Peter Marks, and Acting Under Secretary of Commerce for Standards and Technology and Acting NIST Director Kent Rochford.

In addition, attendees were treated to industry perspectives through plenary presentations and a roundtable featuring leaders in biopharmaceutical manufacturing. Many used the networking opportunities to discuss shared challenges in the industry and opportunities to work collaboratively on solutions.

Since then, NIIMBL has defined and prioritized some of the industry’s technology and workforce needs and launched projects to address them. The plan is to build a technology roadmap for the industry, continuing that work through 2018.

“The collaborative aspect of NIIMBL will be essential to solving today’s biomanufacturing challenges and creating an environment where this industry can thrive, particularly in the U.S.”

—Kelvin Lee, NIIMBL Director

MORE STORIES

2017 Research in Progress

What’s it like to do research in the Arctic? What ‘s it like to be on a ship for 4 to 6 weeks off Greenland? How do you work and sleep with 24 hours of daylight? Oceanographer Andreas Muenchow gives us a glimpse into his world.

At Sea in the Arctic

What’s it like to do research in the Arctic? What ‘s it like to be on a ship for 4 to 6 weeks off Greenland? How do you work and sleep with 24 hours of daylight? Oceanographer Andreas Muenchow gives us a glimpse into his world.

The Quiet Revolution

Trevor A. Dawes learned how libraries can change people’s lives when he was a college student. Now, he’s leading the charge to make the UD Library, Museums and Press an even greater force for good.

The hidden lives within a portrait

A 1746 portrait would launch a global journey into 18th-century life and present the past in a way never done before. The portrait was of Anne Shippen Willing, and what she wore would lead historian Zara Anishanslin on a journey to the far corners of the world—and launch a bold new way of looking at the past.

Filling a Real Demand for Simulated Care

Nursing instructor Amy Cowperthwait and her students are inventing products with a common goal: teaching compassionate patient care. Cowperthwait’s startup links students, engineers, business experts on quest to teach challenging medical procedures.

Suit Me Up for Mars

When astronauts make the “Journey to Mars,” NASA wants every protective measure available in place. The space agency contracted with ILC Dover to develop a new spacesuit, and ILC enlisted several materials experts at the University of Delaware to work on a suit that can handle whatever space might throw at them.

Exploring the Red Planet

NASA wants to put humans on Mars by the early 2030s. University of Delaware researchers are helping to develop spacesuits for that mammoth expedition. Yet Mars is shrouded in mystery for many of us. So what do you know about Mars? Let’s test your knowledge.

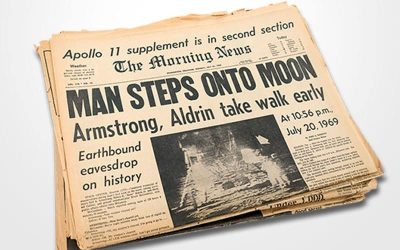

1969 – The Morning News: Man Steps onto Moon

Astronaut Neil A. Armstrong took the first moon step at 10:56 p.m., Delaware time, just six hours and 39 minutes after he and Edwin E. Aldrin Jr. fulfilled the age-old dream of landing on the moon. This was a major milestone in the new era of space exploration. We invite you to explore this interactive experience and relive the excitement of the first moon landing.

News Briefs

Learn how UD researchers are sharpening that competitive edge, fighting brain cancer, giving credit where credit is due, partners in disaster research and UD-NUVVE collaboration

Partnerships in progress

Multiple partnerships took wing in the past year to ensure UD’s scholarly efforts have the broadest and most sustained impact. Learn about the collaborations that ensure a UD world-class educational experience while serving as a major force for economic development.

Honors

Eight UD professors recently received the National Science Foundation’s highly competitive CAREER Award, which is given to scientists and engineers who exemplify the role of teacher-scholars through their outstanding research and teaching.