Research & Discovery

Research & Discovery

A Blog Devoted to UD Innovation, Excellence and Scholarship

Research & Discovery

A Blog Devoted to UD Innovation, Excellence and Scholarship

Why are gels elastic?

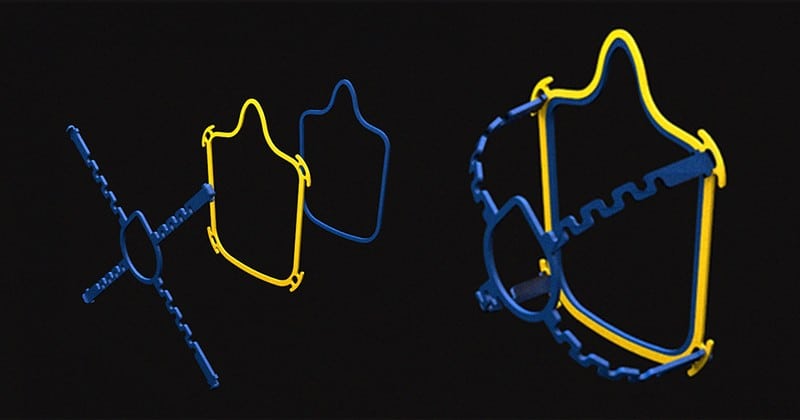

ABOVE: A team of scientists, including UD’s Eric Furst, discovered that the elasticity of gels arises from the packing of clusters of particles in the gels, which the group dubbed locally glassy clusters. | Illustration by Joy Smoker

New research shows how clustered particles determine elasticity of some gels

However, until now, scientists have been unable to explain the microscopic structures within gels that impart their elasticity, or springiness, nor how those structures form. A team of scientists from the University of Delaware, Massachusetts Institute of Technology, North Carolina State University and University of Michigan discovered that the elasticity of gels arises from the packing of clusters of particles in the gels, which the group dubbed locally glassy clusters.

This research, described in a paper published in the journal Nature Communications, could help people engineer better materials and products at the microscale. This insight could help companies in the consumer products, biotechnology, and agriculture sectors and beyond.

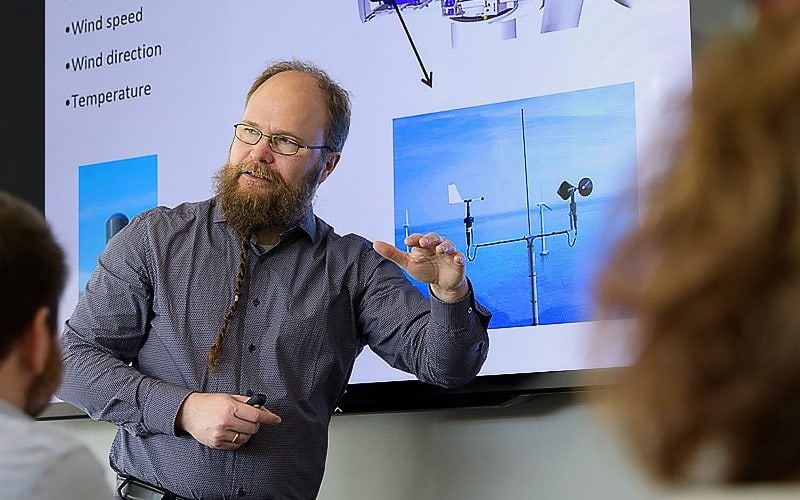

Many companies formulate and sell gel products, and sometimes, the stiffness of gels changes as a result of instability. Eric Furst, professor and chair of UD’s Department of Chemical and Biomolecular Engineering and one of the paper’s corresponding authors, keeps an old bottle of fabric softener on a shelf in his office and uses it to demonstrate what happens when gels separate or “collapse”. The product is supposed to be easy to pour, but when it goes bad, it becomes gloppy and unappealing.

“Our results provide insight into how to engineer cluster size distribution to control stiffness, flow, and stability of gel materials,” said Furst.

The first author of the new paper is Kathryn A. Whitaker, who received a doctoral degree in chemical engineering from UD in 2015 and is now a senior research engineer at Dow in Midland, Michigan.